Hyderabad

+91-9866673432

info.kipl.india@gmail.com

Equipment overview:

Roll Forming Machine is a specialized tool used in the industrial sector, especially for producing metal profiles or sheets with uniform cross sections.

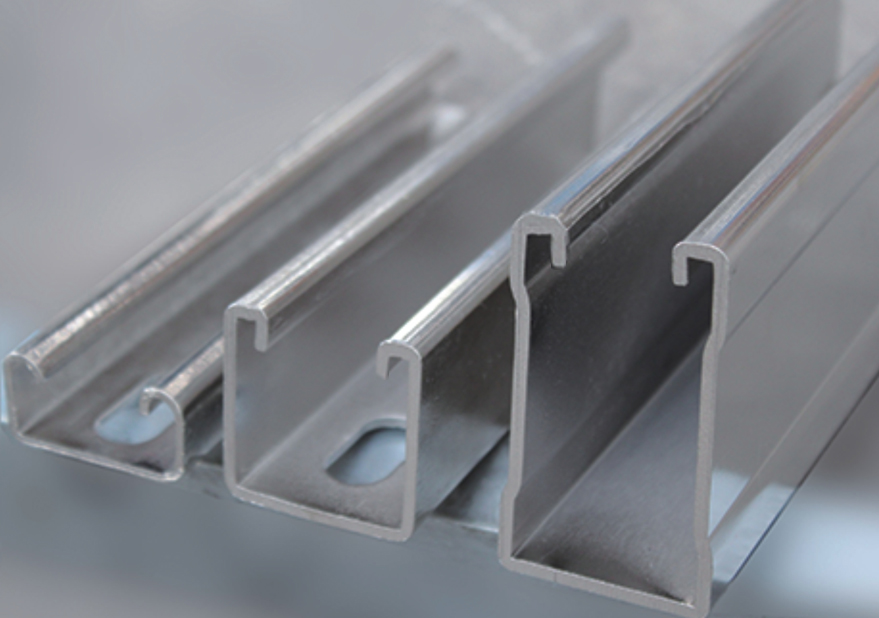

Shutter Patti Roll forming machine.

Profiles: Half Round, Box and Flat Profiles.

Extra Designs: Name Stamping Embossing Roller, Design Embossing Roller.

Roll forming machine Designer and manufacturer

Our products includes a wide range of Rolling Shutter Roll Profile Forming Machine, Metal Door Frame Roll Forming Machine, C To Z Purlin Roll Forming Machine and Roofing Sheet Profile Roll Forming Machine

Equipment overview:

1. With two cantilever gear drives, the machine’s generating width may be continuously adjusted, allowing for height and width adjustments.

2. There are 20 stages in the rolling stations. The primary machine is made up of an AC motor, a reducer, a high-precision liner rail, left and right transmission boxes, a horizontal adjustment system, and rolling molds. The roller is made of 45# steel, and the machine base and transmission have a welding construction with hardness treatment.

3. The roll forming craft is created using the unique COPRA cold roll forming program in Germany; a FEA analysis and check are also produced for the craft. Because the rollers’ structures are integrated, there is little variation in the roll-forming resisting force and line speed. Feeding the sheet is simple. These all guarantee the accuracy and stable of the roll forming.

| Machine Type | Fully Automatic |

| Job Thickness | 0.5 mm |

| Material | Mild Steel |

| Max Sheet Width | 400mm |

| Production Capacity | 18 Meter Per Minute |

| Automation Grade | Automatic |

| Phase | Three Phase |

| Voltage | 440 V |

| Frequency | 60 Hz |

| Machine Type | Fully Automatic |

| Job Thickness | 0.5 mm |

| Material | Mild Steel |

| Max Sheet Width | 400mm |

| Production Capacity | 18 Meter Per Minute |

| Automation Grade | Automatic |

| Phase | Three Phase |

| Voltage | 440 V |

| Frequency | 60 Hz |

| Type of Rolling Machine | Shutter Rolling Machine |

| Production Capacity | Up to 3 ton/day |

| Capacity | 1.5 -2 Ton |

| Automatic Grade | Manual |

| Coil Type | 121, 125, 127 |

| Country of Origin | Made in India |

| Material | Stainless Steel |

| Cutting Type | Fully Automatic |

| Number Of Forming Stations | 14 |

| Job Thickness | 1-2 mm |

| Max Sheet Width | 80 – 300 mm |

| Automation Grade | Automatic |

| Max Sheet Width | 800mm |

| Capacity | 30 Ton |

| Material | Stainless Steel |

| Cutting Type | Fully Automatic |

| Voltage | 440V |

| Machine Weight | 5000 Kg |

| Power Consumption | 30 kW |

| Frequency | 50Hz |

| Power Source | AC |

| Usage/Application | Industrial Use |

| Phase | 3 Phase |

| Material | PPGI |

| Usage/Application | For Roofing sheet roll forming |

| Model Name/Number | Roofing Sheet Roll forming mcahine |

| Capacity | 18 Meter / Minute |

| Automation Grade | Automatic |

| Coil Weight | 5000 Kg |

| Mandrel Movement | 508mm to 550mm |

| System Control | HMI touch control with PLC |

| Total Hp For Line | 15HP |

| Warranty | 2 Years |

| Brand | KONEET |

| Maximum sheet thickness in CRCA Strips that can be formed | 0.6mm |

| Country of Origin | Made in India |

Copyright © 2023 Koneet Industries Private Limited. All rights reserved. Build with

WhatsApp us